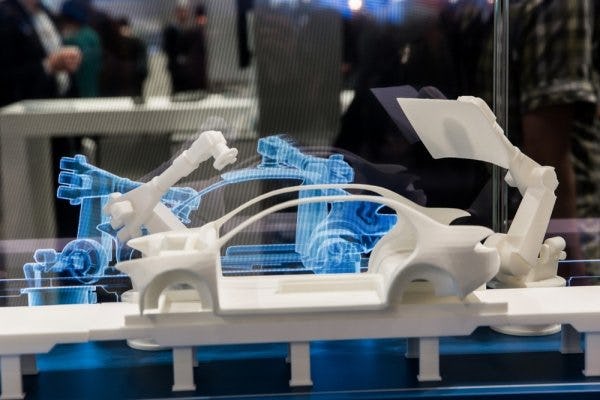

The realistic elements of Virtual Reality (VR) allow engineers and designers to analyze how a new product would look and behave without the need to build the model.

Industry

Product design safety

- Speed up problem identification

- Reduction of physical prototypes and cost savings

- Reduction of design and ergonomic errors

- Reduction of the design cycle and time-to-market

related products

Training, protocols and simulations

The programming of environments in Virtual Reality (VR) allows the visualization of training programs to obtain a faster learning curve; the creation of protocol programs to minimize errors and visualize specific and repetitive tasks; the simulation of dangerous situations to increase safety and efficiency at work and reduce occupational risks.

- Standardize procedures and replace physical manuals

- Reduction of accidents and / or occupational risks

- Reduction of personnel required for training

- Physical barriers no longer exist

related products

Machine clones

Virtual Reality (VR) allows creating virtual clones of machines for real-time analysis of data and process and manufacturing workflows. It is also used to visualize “step by step” maintenance by creating an immersive dynamic 3D data visualization system.

- Reduces diagnostic and troubleshooting time

- Increase in design iterations

- Product functionalities validation

- Increase business agility and flexibility